Crunchy Flavorful Snack

Versatile in Recipes

Satisfying

Treat

Portable and Convenient

Nutrient

Rich

Vibrant and Appealing

Harvesting

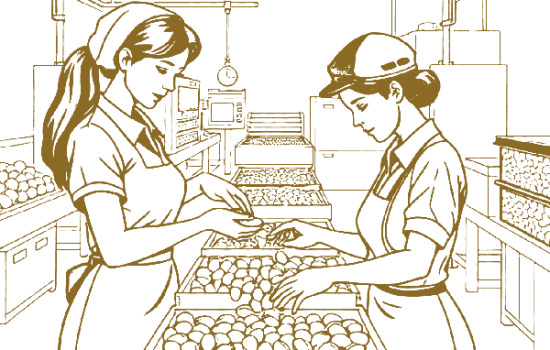

Pistachios are harvested, dehulled, cleaned, dried, sorted, and packaged to ensure quality and readiness for market.

Shelling

Grading

Packing

Dehulling

Crunchy and Flavorful Snack

Versatile in Recipes

Satisfying

Treat

Portable and Convenient

Nutrient

Rich

Vibrant and Appealing

Harvesting

Pistachios are harvested when the shells naturally split, indicating ripeness. They are collected by shaking the trees, then quickly dehulled, cleaned, and dried to retain quality. Finally, the nuts are sorted and packaged for market.

Shelling

In the pistachio shelling process, the nuts are cracked open to separate the edible kernel from the hard shell. The cracked nuts are then sorted to remove any damaged or unripe ones. Finally, the pistachios are cleaned and prepared for packaging or further processing.

Grading

Pistachios are graded based on size, color, and quality to ensure uniformity. The nuts are sorted to remove damaged, underdeveloped, or broken ones. This ensures only the best pistachios are selected for packaging or further processing.

Packaging

At the final stage, pistachios are carefully cleaned and undergo quality checks to ensure only the best nuts are selected. They are then packed in moisture-proof, airtight packaging to maintain freshness and extend shelf life.

Dehulling

Dehulling pistachios involves removing the outer shell through mechanical cracking or gentle shaking. This process enhances the nut’s flavor, makes it easier to eat, and improves its shelf life by preventing moisture absorption.