Versatile Ingredient

Rich in Natural Goodness

Tasty Guilt Free

Natural Sweetness

Long Shelf Life

Energy

Boost

Grape selection

Drying

Cleaning

Grading

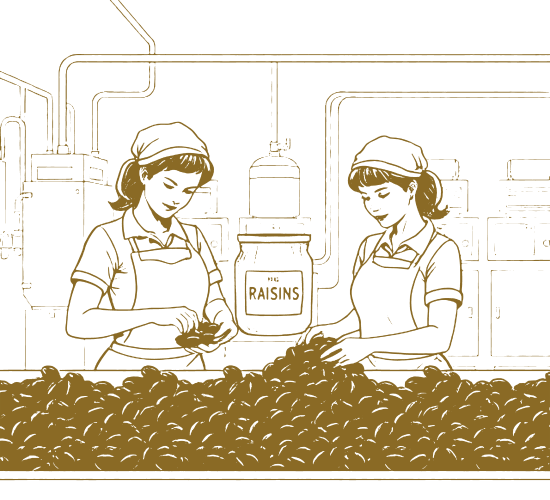

Packaging

Versatile Ingredient

Rich in Natural Goodness

Perfect for Guilt-Free Snacking

Natural Sweetness

Long Shelf

Life

Energy

Boost

Grape selection

Grapes are carefully selected based on ripeness, size, and quality to ensure premium results. Only the best grapes are chosen for raisin production, undergoing cleaning and drying processes. This transforms them into sweet, nutritious raisins ready for packaging.

Drying

After sourcing high-quality grapes, they are washed and dried under controlled conditions to reduce moisture content. This prevents spoilage and extends the shelf life of the raisins while preserving their natural sweetness and texture.

Cleaning

High-quality grapes are carefully selected and thoroughly washed to remove impurities. After washing, they are dried under controlled conditions to reduce moisture content. This process helps prevent spoilage, ensuring the raisins retain their natural sweetness and texture.

Grading

Raisins are graded based on size, color, and quality to ensure consistency. The raisins are carefully sorted to remove any damaged or overripe ones. This ensures that only the finest raisins are selected for packaging or further processing.

Packaging

At the final stage, raisins are meticulously cleaned and undergo thorough quality checks to ensure only the best are selected. They are then packed in moisture-proof, airtight packaging to preserve their freshness. This packaging helps extend the shelf life of the raisins.